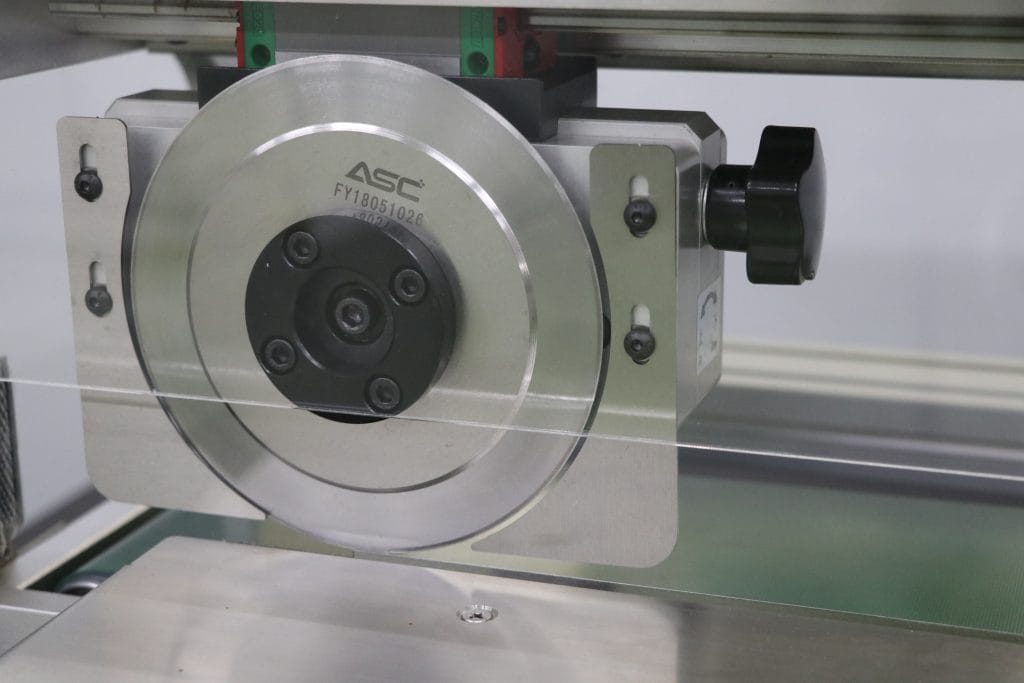

In the realm of printed circuit board (PCB) manufacturing, precision and efficiency are paramount. To meet these demands, we present the I.C.T-MBV360, a state-of-the-art V Groove Cutting Machine, also referred to as the Moving Blade PCB Depaneling Machine. This exceptional piece of machinery, featuring a circular blade and cutting-edge technology, revolutionizes the process of PCB separation.

Cutting-Edge Technology

The I.C.T-MBV360 is engineered to perfection, leveraging cutting-edge technology to ensure high stability and pinpoint accuracy in positioning. Controlled by a microcomputer, it delivers consistent and reliable results every time, making it an indispensable tool for PCB manufacturers.

Enhanced Speed And Precision

One of the standout features of this machine is its ability to operate at higher speeds, significantly improving cutting results and eliminating burrs on the PCBs. The precision of the blade height adjustment, ranging from 0 to 2mm, and the platform height adjustment from 0 to 50mm, caters to PCBs of varying thicknesses and V-slot depths, thus ensuring versatility and adaptability.

Customizable Length Stop

Users have the flexibility to manually set the position for automatic stoppage, allowing for tailored cutting according to the specific length of the PCB. This feature enhances the machine’s efficiency and precision in PCB separation.

V Groove Cutting Machine Versatility And Adaptability

The I.C.T-MBV360 boasts a wide range of capabilities. It accommodates PCBs of different widths, with no restrictions, and can handle a maximum thickness among V-slots ranging from 0.25 to 2.0mm. This adaptability makes it suitable for a diverse range of PCB manufacturing needs.

Durable Blades And Optional Conveyor Belt

The machine is equipped with imported high-speed steel blades that are not only incredibly durable but also capable of being sharpened when needed, ensuring long-term cost-effectiveness. Additionally, an optional conveyor belt facilitates the convenient transfer of finished PCBs to a designated location, streamlining the production process.

Enhanced Efficiency With Stop Blocks

The I.C.T-MBV360 comes with stop blocks designed to accommodate different PCBs, further enhancing overall workflow efficiency. Whether you are working with a single PCB or a batch of diverse sizes, this machine has you covered.

In conclusion, the I.C.T-MBV360 V Groove Cutting Machine is a pinnacle of precision, efficiency, and adaptability in the field of PCB manufacturing. With its advanced features, customizable options, and durable construction, it stands as a testament to our commitment to delivering top-notch solutions for your PCB separation needs. Embrace the future of PCB manufacturing with the I.C.T-MBV360 and experience the difference it makes in your production processes.

Ready to elevate your PCB manufacturing process? Contact us today to learn more about the I.C.T-MBV360 and how it can revolutionize your operations. Don’t miss out on the opportunity to enhance your efficiency and precision in PCB separation.

0 Comments